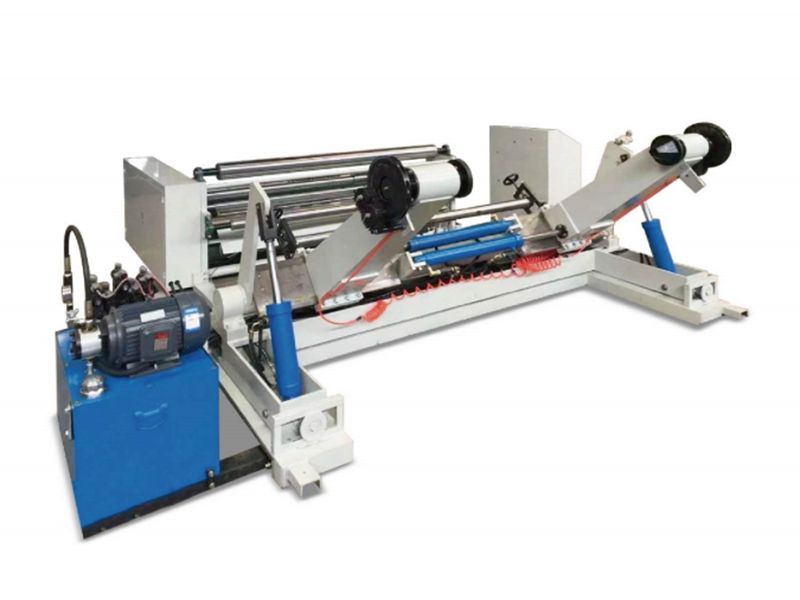

Horizontal Slitter Rewinder XKFQ-1600

High Speed Roll-to-Roll Paper Slitting and Rewinding

XKFQ-1600 horizontal slitter rewinder is constructed to convert a wide range of large diameter roll products like kraft paper and printed paper to narrow rolls through unwinding, slitting and rewinding processes. This paper roll slitting machine is configured with functions of tension control, automatic edge alignment, automatic web guiding and automatic knife positioning, which result in optimal effect and increased performance while ensuring the slitter rewinder machine runs more stable, smooth, easier and safer. The highlighted feature of this high speed slitter is hydraulic shaftless unwind stand, which enables the paper rolls to be unwinded and rewinded much easier and faster.

- Model: XKFQ-1600

- Web width: 1600mm

- Max. Rewinding diameter: Φ1300mm

- Max. Unwinding diameter: Φ1300mm

- Paper core diameter: Φ76mm

- Slitting Speed: 200m/min

- Automatic tension setting range: 0-200N.m

- Slitting precision: <0.1 mm

- Total power: 12kw

- Weight: 4000kg

- Overall dimensions (L×W×H): 3500×3000×1000

- The robust structure is built by welding of thick steel plates, providing a balanced web wrap angle while ensuring the machine operates stably and keeps paper roll aligned accurately under high speed.

- All rollers are made of chrome-plated steel tubes whose surface is ground and dynamically balanced.

- The unwinding unit uses 3-inch tapered core chuck to achieve shaftless unwinding, the maximum unwinding diameter can reach 1300mm. Besides, the unit is equipped with automatic edge alignment, automatic web guiding, automatic knife positioning and manual tension control as standard configurations. The automatic tension control with magnetic particle brake is optional as per customer's request.

- 3-inch air shaft and tension control are used to control rewinding and slitting process, significantly facilitating the operation. The rewinding diameter is up to 1300mm.

- The slitting units is fitted with upper and lower rotary knives that are adjustable with a range of 30mm-1600mm (or customized within 10-1600mm).

- Stepless speed regulation of frequency converter is achievable for main shaft and rotary knives, PLC digital control and touch screen make the setting of mass production simple and easy.

- High precision ball screw and slide rail enable the cutting width to be aligned in parallel, servo motor is adopted to achieve stepless adjustment of cutting speed, therefore ensuring high cutting precision within 0.1mm.

- Taiwan Delta frequency converter and PLC system, Kunlun Tongtai touch screen, Japan NACHI bearings and China renowned Harbin bearings are the factors playing a vital role in ensuring premium quality.

- Chinese and English operation interface allows operator to input 8 different cutting widths and desired quantities, the design of switching function between manual and automatic operation makes the slitting process flexible and convenient.

- The loading and unloading of paper rolls are carried out with pneumatic tension control, the process is implemented with only one action, thus efficiently reducing the labor intensity while enhancing the production efficiency.

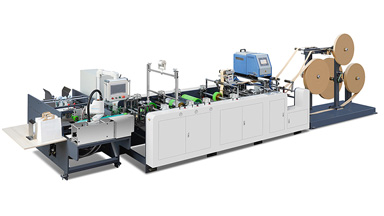

Xinke is a company specializing in engineering and manufacturing paper bag machinery. Apart from our block bottom SOS bag making machines and flat & satchel paper bag making machines, we also supply a range of in-line printing machines and complementary equipment related to paper bag production. As a paper bag machine specialist, we know that individual customer needs and preferences play a major role in staying ahead of the competition. We are nimble enough to satisfy your needs of paper shopping bag production, no matter whether it is with or without handle, twisted handle or flat handle, printed or plain.

-

- Twisted Paper Rope Making MachineOur twisted paper rope making machine is primarily designed to produce twisted paper cords using kraft paper roll as raw material.Learn More

-

- Paper Rope Rewinding MachineXinke paper rope rewinding machine is mainly used for high-speed rewinding of multiple small twisted paper rolls...Learn More

-

- Semi-auto Twisted Handle Making MachineOur semi-auto twisted handle making machine is applied to produce round handles using twisted paper cords and glue.Learn More

-

- Automatic Twisted Handle Making MachineThis automatic twisted handle making machine is ideal for in-line application with paper bag making machine.Learn More

-

- Semi-auto Flat Handle Making MachineThis semi-auto flat handle making machine is capable of turning four rolls of prepared paper into flat paper bag handles in one process.Learn More

-

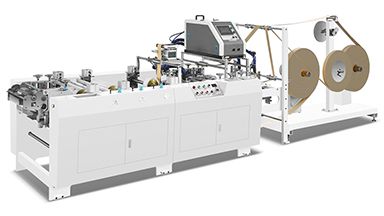

- Automatic Flat Handle Making MachineXKBS-01 automatic flat handle making machine integrates functions of handle making and attaching to the paper bag.Learn More

Founded in 2000, Xinke is a company specialized in developing, manufacturing and supplying a full line of paper bag machinery. Our determination to invest in the paper packaging industry stems from our firm commitment to protecting the environment and moving with high sustainability, and we are willing to make our contribution to promote environmental protection.