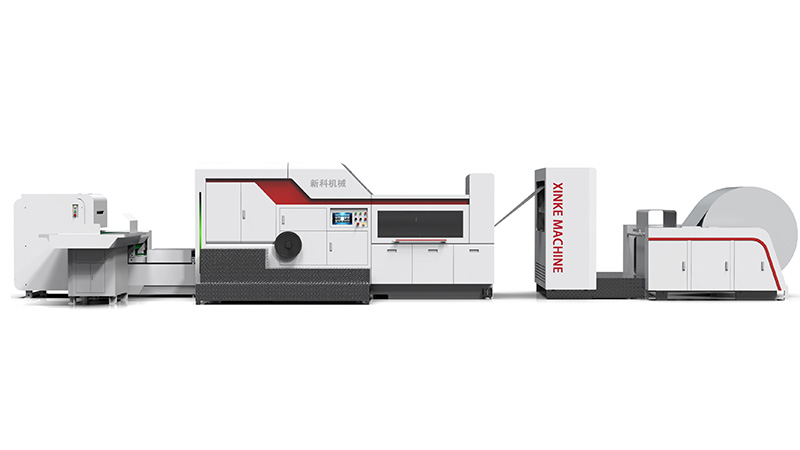

Block Bottom Bag Making Machine XKFD-330D

Roll-fed Paper Bag Making Machine for Square Bottom Bag & SOS Bag with Die Cut Handles

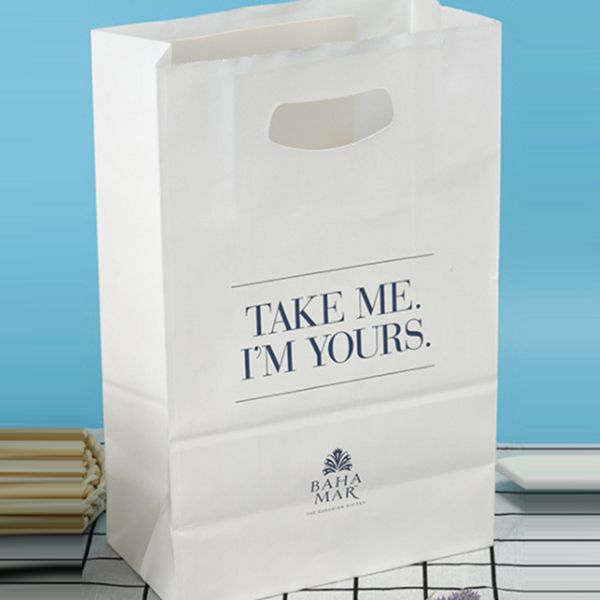

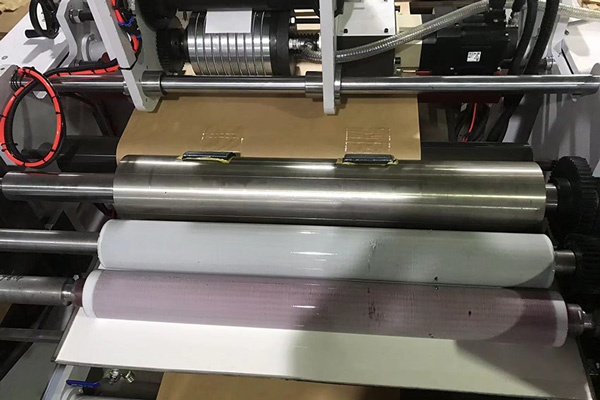

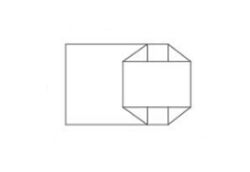

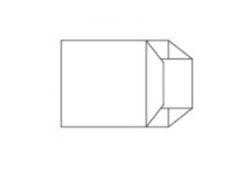

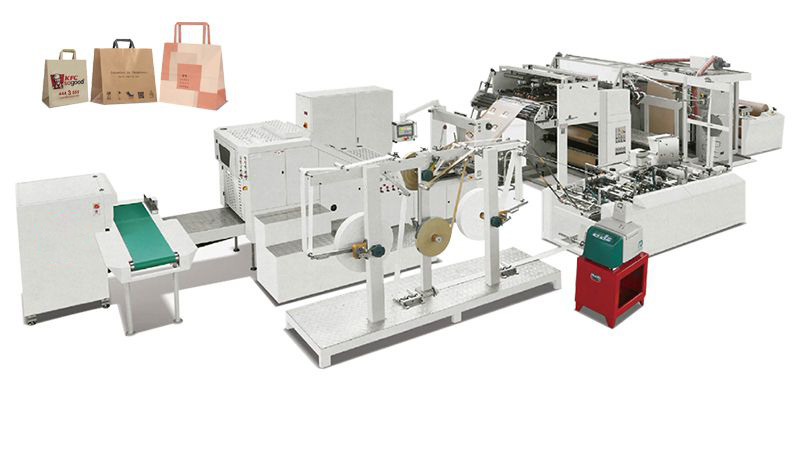

This block bottom bag making machine was developed in response to the market needs of die-cut handle bags by equipping with die-cut handle making unit. It is a roll-fed paper bag making machine that uses blank paper roll or printed paper roll as raw materials. The use of PC programmable servo motor system coupled with touch screen HMI interface makes the paper bag production to be easily carried out in one process, including paper roll unwinding, pre-cutting of die-cut handle, side gluing, forming, cutting, bottom gluing and final bag collecting.

In addition to making paper carrier bags with die-cut handles, this paper bag machine can also manufacture paper shopping bags without handles by simply cancel the function of handle making via the touch screen, which is an ideal solution for paper packaging manufacturers who specialize in paper bag production.

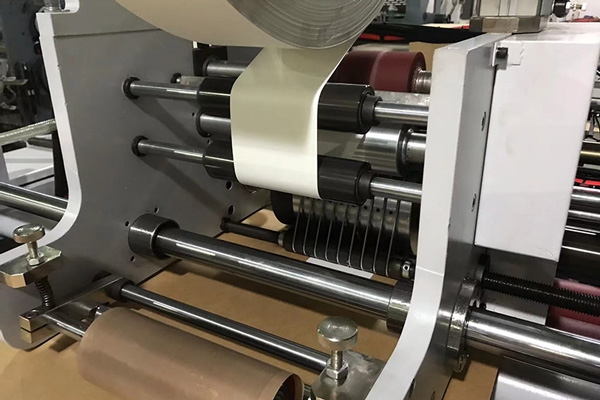

Unwinding

Unwinding Side gluing

Side gluing Tube forming

Tube forming Cut off

Cut off Creasing

Creasing Bottom opening

Bottom opening Bottom gluing

Bottom gluing Bottom folding

Bottom folding Final bag

Final bag

- Model: XKFD-330D

- Paper roll length (c): 270-530mm

- Paper bag length (l): 225-470mm

- Paper bag width (w): 150-330mm

- Paper bag bottom width (h): 60-180mm

- Paper thickness: 60-160g/m2

- Machine speed: 30-120pcs/min

- Die cut handle bag width: 190-330mm

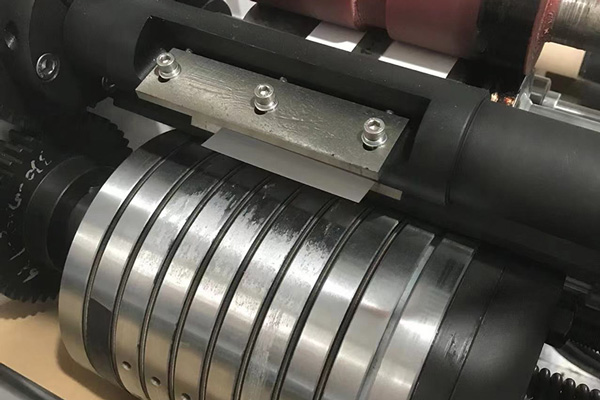

- Die cut handle opening size: 80-90mmx30mm

- Patch paper thickness: 100-150g/m2

- Patch film thickness: 0.3-0.6mm

- Patch paper roll width: 150mm

- Patch paper roll unwinding diameter: 500mm

- Paper roll width: 450-1050mm

- Paper roll diameter: 1200mm

- Diameter of paper core: 76mm (3")

- Machine power: 3phase, 380v, 12kw

- Machine weight: 8000kg

- Machine size: 10500x3700x1900mm

The paper bag making machine is designed with a unit for reinforced patch handle, which can be optionally operated.

The paper block bottom bags that come out of our paper bag machinery are available in various shapes and sizes, offering endless packaging options for those who are looking for paper packaging solutions. As a paper bag machinery manufacturer, Xinke can offer flexo in-ling printers to help customers add their logos or designs for brand promotion.

-

- Flat and Satchel Paper Bag Making MachineThis flat and satchel paper bag making machine can automatically accomplish the entire process in one pass, including paper roll unwinding, pre-puncturing, side gluing...Learn More

-

- Flat and Satchel Paper Bag Making Machine(with 2 Color Flexo Printer)Our XKJD350 flat and satchel paper bag making machine was developed in response to the needs of bakery shop, KFC and McDonalds where sharp bottom...Learn More

-

- Pointed Bottom Bag Making MachineXinke XKJD-400 roll-fed paper bag making machine is a general type pointed bottom bag making machine that can manufacture various types of paper food bag in one process.Learn More

-

- Block Bottom Bag Making Machine (SOS Bag with Twisted Handles)These block bottom bag making machines are automatic roll-fed bag making machines developed typically for mass production of paper shopping bags and merchandise bags...Learn More

-

- Block Bottom Bag Making Machine (SOS Bag with Flat Handles)This automatic roll-fed paper bag making machine is currently the most advanced block bottom bag making machine for manufacturing paper carrier bags...Learn More

-

- SOS Paper Bag Making MachineThis paper bag making machine is a block bottom bag machine that uses blank or printed paper roll as raw material to produce various types of paper bag with square bottom.Learn More

Founded in 2000, Xinke is a company specialized in developing, manufacturing and supplying a full line of paper bag machinery. Our determination to invest in the paper packaging industry stems from our firm commitment to protecting the environment and moving with high sustainability, and we are willing to make our contribution to promote environmental protection.