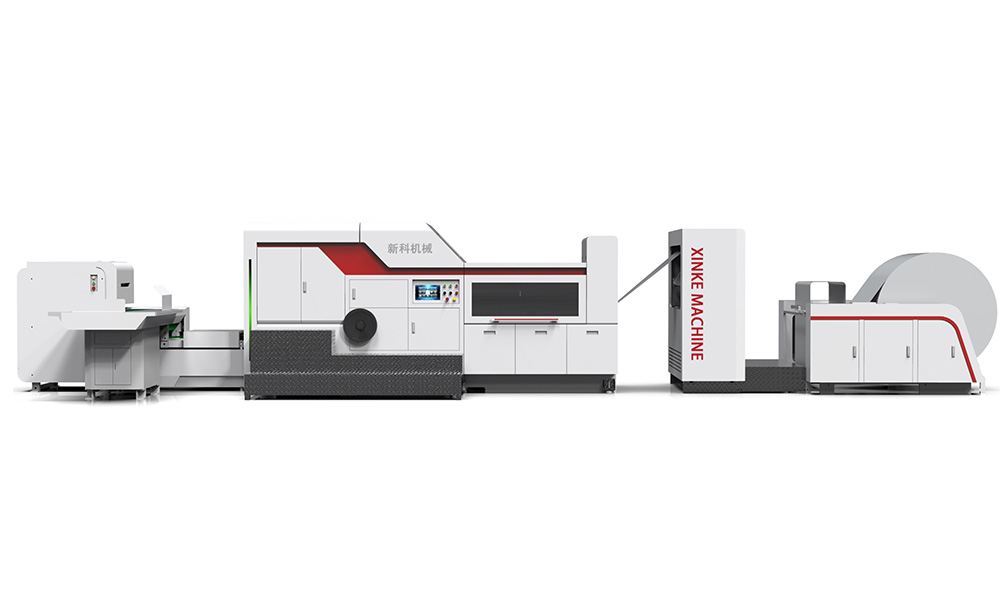

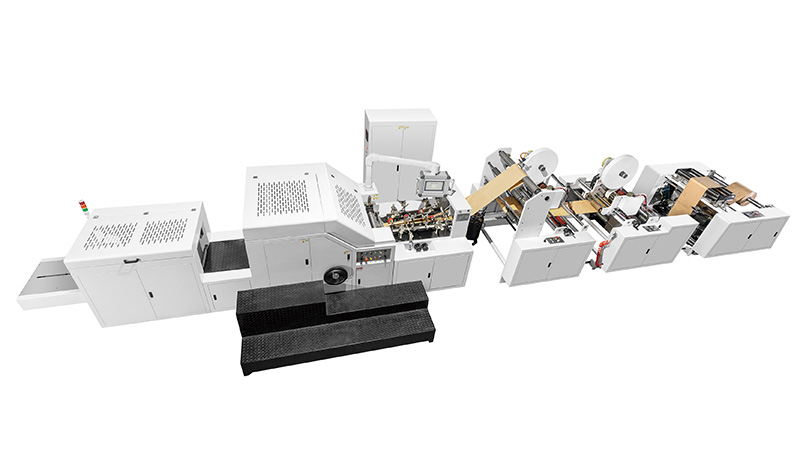

SOS Paper Bag Making Machine XKFD-220/280/330/450/540

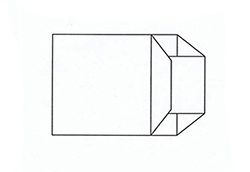

Roll-fed Paper Bag Making Machine for Self Opening Sack (SOS) Bag

This paper bag making machine is a block bottom bag machine that uses blank or printed paper roll as raw material to produce various types of paper bag with square bottom. By adopting Mitsubishi servo motor control system, this paper bag machine can conduct an automatic production process through each step of paper roll unwinding, side gluing, print mark detecting (photoelectric sensor), folding & tube forming, cutting, bottom opening, bottom gluing, bottom forming and final bag collecting.

Our paper bag making machine can be equipped with in-line printer and die cut handle device which enable paper shopping bags or paper carrier bags to be crafted in a wide assortment of styles adapted to user preferences, while adding marketing value to every item.

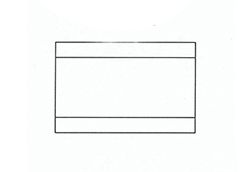

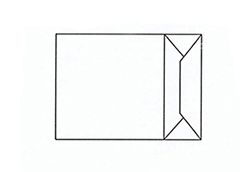

Unwinding

Unwinding Side gluing

Side gluing Tube forming

Tube forming Cut off

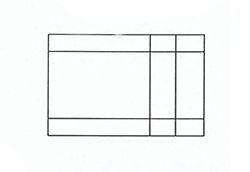

Cut off Creasing

Creasing Bottom opening

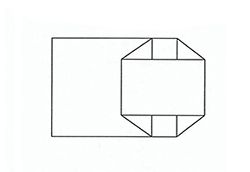

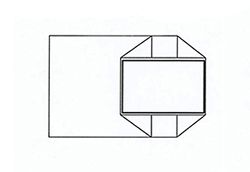

Bottom opening Bottom gluing

Bottom gluing Bottom folding

Bottom folding Final bag

Final bag

- Model:

XKFD-220

- Speed: 30-200pcs/min

- Cutting length: 190-370mm

- Paper bag length : 150-320mm

- Paper bag width : 80-220mm

- Paper bag bottom width : 55-100mm

- Side overlap width: 20-30mm

- Bottom overlap width: 10-20mm

- Paper roll width: 290-670mm

- Paper roll diameter: 1300mm

- Paper thickness: 50-130gsm

- Paper core diameter: 76mm(3")

- Machine power: 10kW

- Air source: 0.06MPa

- Machine weight : 5500kg

- Machine size: 8000x2980x1800mm

- Model:

XKFD-280

- Speed:30-180pcs/min

- Cutting length:270-530mm

- Paper bag length :225-470mm

- Paper bag width :120-280mm

- Paper bag bottom width :60-180mm

- Side overlap width:25-30mm

- Bottom overlap width:15-25mm

- Paper roll width:385-950mm

- Paper roll diameter:1300mm

- Paper thickness:60-160gsm

- Paper core diameter:76mm(3")

- Machine power:12kW

- Air source:0.06MPa

- Machine weight :7000kg

- Machine size:9700x2980x1900mm

- Model:

XKFD-330

- Speed: 30-160pcs/min

- Cutting length: 270-530mm

- Paper bag length : 225-470mm

- Paper bag width : 150-330mm

- Paper bag bottom width : 60-160mm

- Side overlap width: 25-30mm

- Bottom overlap width: 15-25mm

- Paper roll width: 445-1050mm

- Paper roll diameter: 1300mm

- Paper thickness: 60-160gsm

- Paper core diameter: 76mm(3")

- Machine power: 12kW

- Air source: 0.06MPa

- Machine weight : 8000kg

- Machine size: 9800x2980x1900mm

- Model:

XKFD-450

- Speed: 30-150pcs/min

- Cutting length: 285-530

- Paper bag length : 225-470mm

- Paper bag width : 220-460mm

- Paper bag bottom width : 80-220mm

- Side overlap width: 30mm

- Bottom overlap width: 20-30mm

- Paper roll width: 630-1390mm

- Paper roll diameter: 1300mm

- Paper thickness: 80-160gsm

- Paper core diameter: 76mm(3")

- Machine power: 15kW

- Air source: 0.06MPa

- Machine weight : 10000kg

- Machine size: 10200x3150x2200mm

- Model:

XKFD-540

- Speed: 30-120pcs/min

- Cutting length: 420-760mm

- Paper bag length : 320-680mm

- Paper bag width : 250-540mm

- Paper bag bottom width : 120-260mm

- Side overlap width: 30-40mm

- Bottom overlap width: 20-30mm

- Paper roll width: 770-1640mm

- Paper roll diameter:

- Paper thickness: 90-160gsm

- Paper core diameter:

- Machine power: 18kw

- Air source: 0.06MPa

- Machine weight : 13000kg

- Machine size: 11250x3400x2160mm

| Model | XKFD-220 |

XKFD-280 |

XKFD-330 |

XKFD-450 |

XKFD-540 |

| Speed | 30-200pcs/min | 30-180pcs/min | 30-160pcs/min | 30-150pcs/min | 30-120pcs/min |

| Cutting length | 190-370mm | 270-530mm | 270-530mm | 285-530 | 420-760mm |

| Paper bag length | 150-320mm | 225-470mm | 225-470mm | 225-470mm | 320-680mm |

| Paper bag width | 80-220mm | 120-280mm | 150-330mm | 220-460mm | 250-540mm |

| Paper bag bottom width | 55-100mm | 60-180mm | 60-160mm | 80-220mm | 120-260mm |

| Side overlap width | 20-30mm | 25-30mm | 25-30mm | 30mm | 30-40mm |

| Bottom overlap width | 10-20mm | 15-25mm | 15-25mm | 20-30mm | 20-30mm |

| Paper roll width | 290-670mm | 385-950mm | 445-1050mm | 630-1390mm | 770-1640mm |

| Paper roll diameter | 1300mm | ||||

| Paper thickness | 50-130gsm | 60-160gsm | 60-160gsm | 80-160gsm | 90-160gsm |

| Paper core diameter | 76mm(3") | ||||

| Machine power | 10kW | 12kW | 12kW | 15kW | 18kw |

| Air source | 0.06MPa | ||||

| Machine weight | 5500kg | 7000kg | 8000kg | 10000kg | 13000kg |

| Machine size | 8000x2980x1800mm | 9700x2980x1900mm | 9800x2980x1900mm | 10200x3150x2200mm | 11250x3400x2160mm |

-

-

- The automatic web guiding system is used in the unwinding section, which constantly corrects the position of the web. Due to the double photoelectric switch, the motor equipped for the web guiding system doesn’t need to work frequently, significantly reducing energy consumption and improving service life.

-

For more than 20 years we have been a paper packaging machine manufacturer specializing in the paper bag market. We are committed to helping our customers design and manufacture paper bag machines with results beyond their expectations. Whether you need to produce small paper grocery bags, large paper shopping bags, with twisted handle or flat handle, our paper bagging machinery can get the job done efficiently.

-

- SOS Paper Bag Making Machine (with 2 Color Flexo Printer)Equipped with 2 color in-line printer, our SOS paper bag making machine is capable of turning paper roll into custom printed paper shopping bags.Learn More

-

- Block Bottom Bag Making Machine (SOS Bag with Die Cut Handles)This block bottom bag making machine was developed in response to the market needs of die-cut handle bags by equipping with die-cut handle making unit.Learn More

-

- Flat and Satchel Paper Bag Making MachineThis flat and satchel paper bag making machine can automatically accomplish the entire process in one pass, including paper roll unwinding, pre-puncturing, side gluing...Learn More

-

- Flat and Satchel Paper Bag Making Machine(with 2 Color Flexo Printer)Our XKJD350 flat and satchel paper bag making machine was developed in response to the needs of bakery shop, KFC and McDonalds where sharp bottom...Learn More

-

- Pointed Bottom Bag Making MachineXinke XKJD-400 roll-fed paper bag making machine is a general type pointed bottom bag making machine that can manufacture various types of paper food bag in one process.Learn More

-

- Block Bottom Bag Making Machine (SOS Bag with Twisted Handles)These block bottom bag making machines are automatic roll-fed bag making machines developed typically for mass production of paper shopping bags and merchandise bags...Learn More

Founded in 2000, Xinke is a company specialized in developing, manufacturing and supplying a full line of paper bag machinery. Our determination to invest in the paper packaging industry stems from our firm commitment to protecting the environment and moving with high sustainability, and we are willing to make our contribution to promote environmental protection.