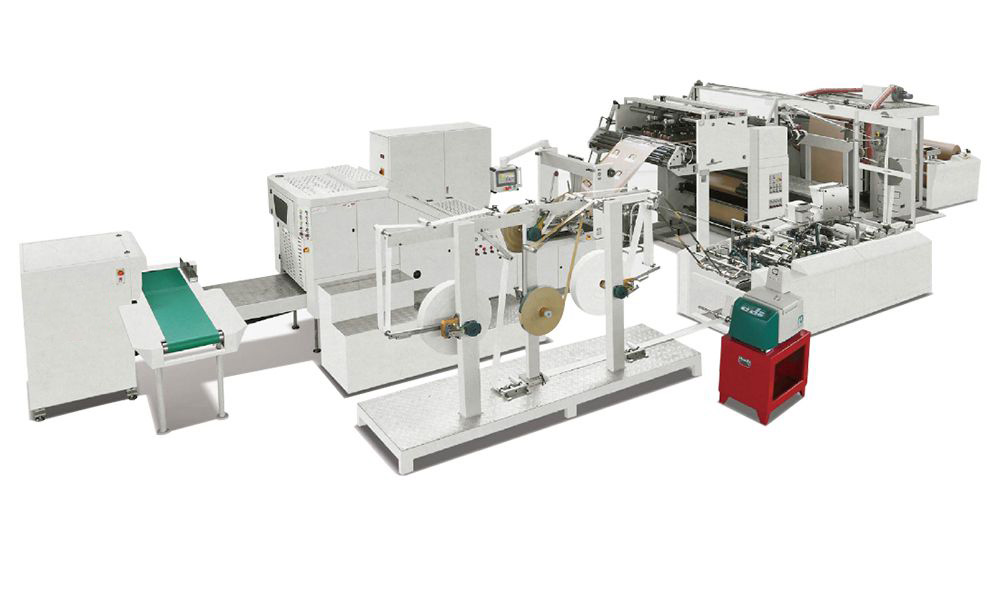

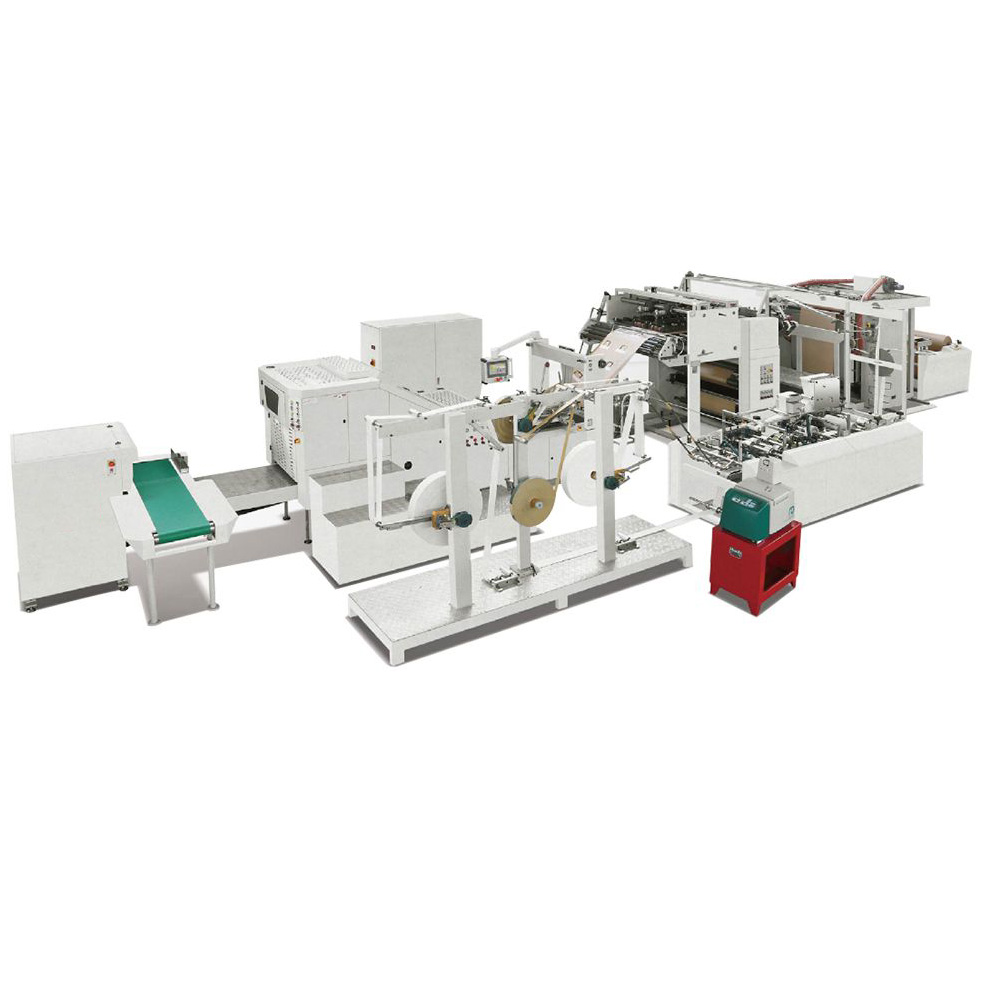

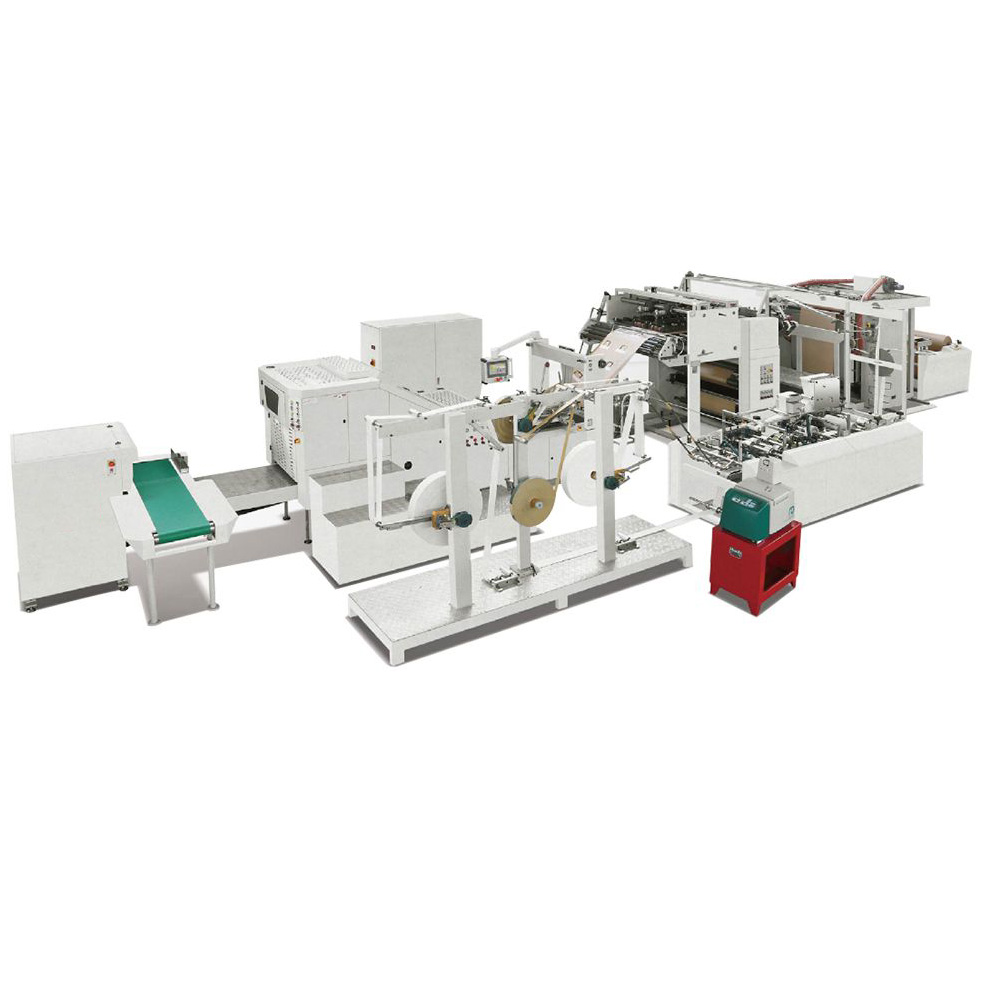

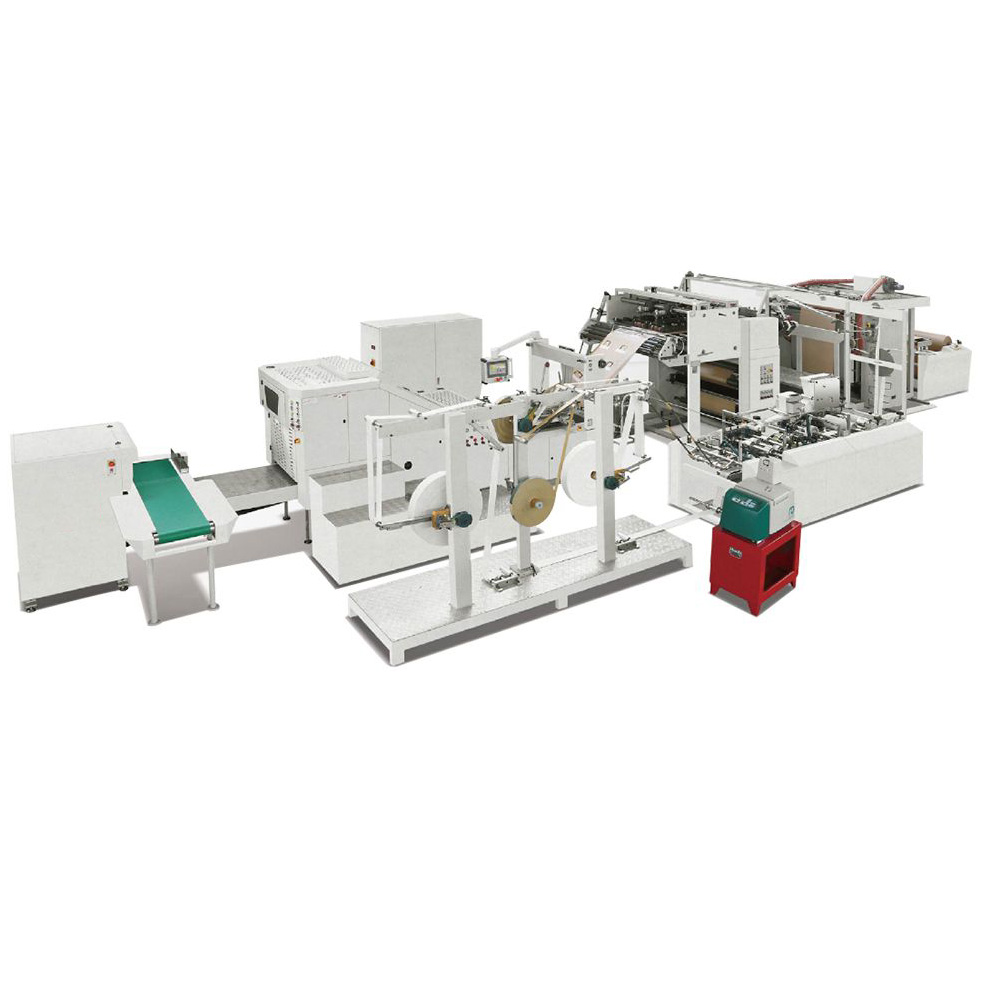

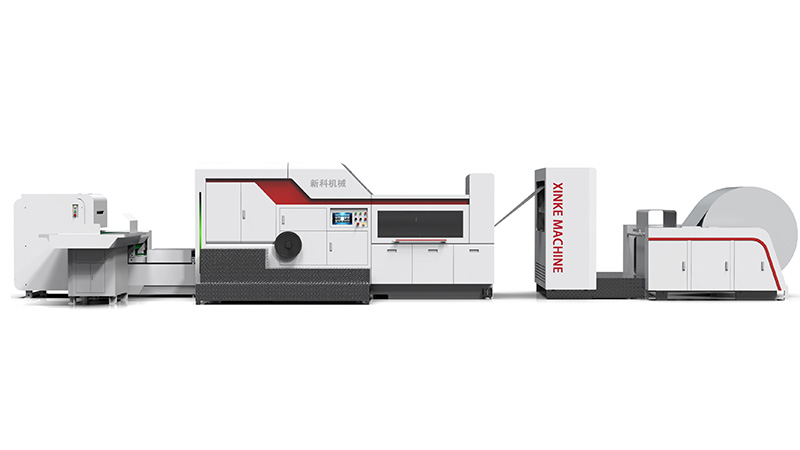

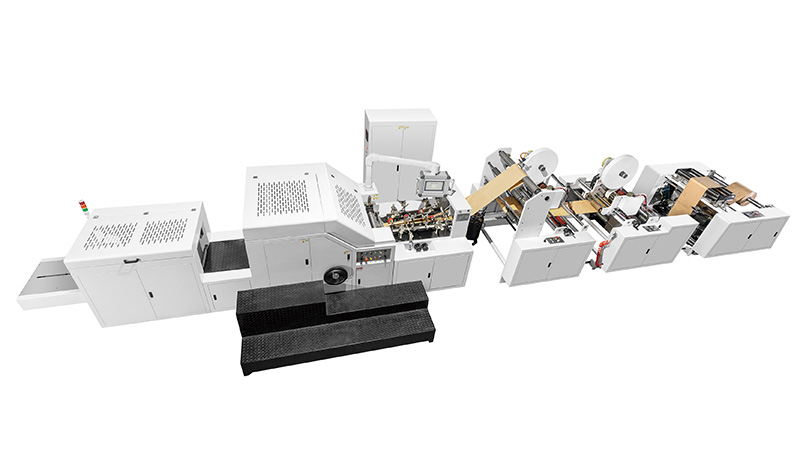

Block Bottom Bag Making Machine XKFD-330F/450F/540F

Automatic Roll-fed Paper Bag Making Machine for Square Bottom Bag & SOS Bag with Flat Handles

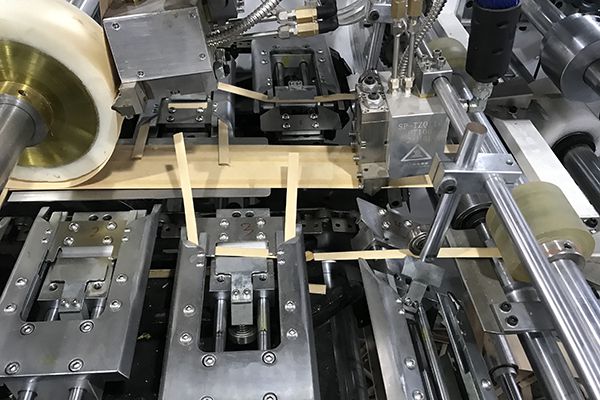

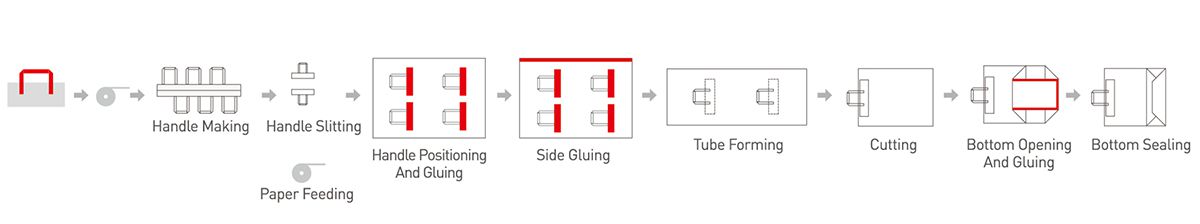

This automatic roll-fed paper bag making machine is currently the most advanced block bottom bag making machine for manufacturing paper carrier bags and paper shopping bags with flat handles. Simply place the blank or printed paper roll, this paper bag making machine will automatically conduct the entire paper bag manufacturing process from flat handle making, patch attaching, side gluing, cutting, bag forming through to completion. The paper bag machinery adopts servo motor control system to ensure high precision and good stability, and PLC control system is used to adjust the length of paper bag.

- Model:

XKFD-330F

- Cut-off length: 270-530mm

- Cut-off length (handle): 270-430mm

- Bag width: 120-330mm

- Bag width (handle): 200-330mm

- Bottom width: 60-180mm

- Paper thickness: 60-150g/㎡

- Paper thickness (handle): 80-150g/㎡

- Paper roll width: 380-1050mm

- Paper roll width (handle): 570-1050mm

- Paper core diameter: Φ 76mm

- Paper roll diameter: Φ 1200mm

- Handle center distance: 78mm

- Flat handle width: 12mm

- Flat handle height: 100mm

- Patch width: 50mm

- Patch length: 152mm

- Flat handle length: 352mm

- Patch paper roll width: 100mm

- Patch paper thickness: 120g/㎡

- Handle paper roll diameter: 1200mm

- Production speed for bags with handles: 30-110pcs/min

- Production speed for bags without handles: 30-180pcs/min

- Machine speed: 30-200pcs/min

- Cutting type: Sawtooth cutting

- Power supply: 380v 3phase 4line 41.5kw

- Machine weight: 16000kg

- Machine size: 14000×6000×2400mm

- Model:

XKFD-450F

- Cut-off length: 270-530mm

- Cut-off length (handle): 270-430mm

- Bag width: 220-450mm

- Bag width (handle): 240-450mm

- Bottom width: 90-180mm

- Paper thickness: 80-150g/㎡

- Paper thickness (handle): 80-150g/㎡

- Paper roll width: 650-1290mm

- Paper roll width (handle): 690-1290mm

- Paper core diameter: Φ 76mm

- Roll paper diameter: Φ 1200mm

- Handle center distance: 85mm

- Flat handle width: 12mm

- Flat handle height: 100mm

- Patch width: 50mm

- Patch length: 190mm

- Flat handle length: 352mm

- Patch paper roll width: 100mm

- Patch paper thickness: 120g/㎡

- Handle paper roll diameter: 1200mm

- Production speed for bags with handles: 30-90pcs/min

- Production speed for bags without handles: 30-150pcs/min

- Machine speed: 30-180pcs/min

- Cutting knife: Sawtooth cutting

- Power supply: 380V 3phase 4line 41.5kW

- Machine weight: 16000kg

- Machine size: 14000×6000×2400mm

- Model:

XKFD-540F

- Cut-off length: 380-760mm

- Cut-off length (handle): 380-660mm

- Bag width: 220-540mm

- Bag width (handle): 240-540mm

- Bottom width: 80-220mm

- Paper thickness 80-150g/m²

- Paper thickness (handle): 80-150g/m²

- Paper roll width: 620-1370mm

- Paper roll width (handle): 670-1370mm

- Paper core diameter: Φ 76mm

- Paper roll diameter: Φ 1200mm

- Handle center distance: 85mm

- Flat handle width: 12mm

- Flat handle height: 100mm

- Patch width: 50mm

- Patch length: 190mm

- Flat handle length: 352mm

- Patch paper roll width: 100mm

- Patch paper thickness: 120g/m²

- Handle paper roll diameter: 1200mm

- Production speed for bags with handles: 30-90pcs/min

- Production speed for bags without handles: 30-100pcs/min

- Machine speed: 30-150pcs/min

- Cutting knife: Serrated cutting

- Power supply: 380V 3phase 4line 41.5kW

- Machine weight: 16600kg

- Machine size: 16100×6500×2400mm

| Model | XKFD-330F | XKFD-450F | XKFD-540F |

| Cut-off length | 270-530mm | 270-530mm | 380-760mm |

| Cut-off length (handle) | 270-430mm | 270-430mm | 380-660mm |

| Bag width | 120-330mm | 220-450mm | 220-540mm |

| Bag width (handle) | 200-330mm | 240-450mm | 240-540mm |

| Bottom width | 60-180mm | 90-180mm | 80-220mm |

| Paper thickness | 60-150g/m² | 80-150g/m² | 80-150g/m² |

| Paper thickness (handle) | 80-150g/m² | 80-150g/m² | 80-150g/m² |

| Paper roll width | 380-1050mm | 650-1290mm | 620-1370mm |

| Paper roll width (handle) | 570-1050mm | 690-1290mm | 670-1370mm |

| Paper core diameter | Ø76mm | Ø76mm | Ø76mm |

| Paper roll diameter | Ø1200mm | Ø1200mm | Ø1200mm |

| Handle center distance | 78mm | 85mm | 85mm |

| Flat handle width | 12mm | 12mm | 12mm |

| Flat handle height | 100mm | 100mm | 100mm |

| Patch width | 50mm | 50mm | 50mm |

| Patch length | 152mm | 190mm | 190mm |

| Flat handle length | 352mm | 352mm | 352mm |

| Patch paper roll width | 100mm | 100mm | 100mm |

| Patch paper thickness | 120g/m² | 120g/m² | 120g/m² |

| Handle paper roll diameter | 1200mm | 1200mm | 1200mm |

| Production speed for bags with handles | 30-110pcs/min | 30-90pcs/min | 30-90pcs/min |

| Production speed for bags without handles | 30-180pcs/min | 30-150pcs/min | 30-100pcs/min |

| Machine speed | 30-200pcs/min | 30-180pcs/min | 30-150pcs/min |

| Bottom folding type |  |  |  |

| Cutting knife | Serrated cutting | Serrated cutting | Serrated cutting |

| Power supply | 380V 3phase 4line 41.5kW | 380V 3phase 4line 41.5kW | 380V 3phase 4line 41.5kW |

| Machine weight | 16000kg | 16000kg | 16600kg |

| Machine size | 14000×6000×2400mm | 14000×6000×2400mm | 16100×6500×2400mm |

-

- SOS Paper Bag Making MachineThis paper bag making machine is a block bottom bag machine that uses blank or printed paper roll as raw material to produce various types of paper bag with square bottom.Learn More

-

- SOS Paper Bag Making Machine (with 2 Color Flexo Printer)Equipped with 2 color in-line printer, our SOS paper bag making machine is capable of turning paper roll into custom printed paper shopping bags.Learn More

-

- Block Bottom Bag Making Machine (SOS Bag with Die Cut Handles)This block bottom bag making machine was developed in response to the market needs of die-cut handle bags by equipping with die-cut handle making unit.Learn More

-

- Flat and Satchel Paper Bag Making MachineThis flat and satchel paper bag making machine can automatically accomplish the entire process in one pass, including paper roll unwinding, pre-puncturing, side gluing...Learn More

-

- Flat and Satchel Paper Bag Making Machine(with 2 Color Flexo Printer)Our XKJD350 flat and satchel paper bag making machine was developed in response to the needs of bakery shop, KFC and McDonalds where sharp bottom...Learn More

-

- Pointed Bottom Bag Making MachineXinke XKJD-400 roll-fed paper bag making machine is a general type pointed bottom bag making machine that can manufacture various types of paper food bag in one process.Learn More

Founded in 2000, Xinke is a company specialized in developing, manufacturing and supplying a full line of paper bag machinery. Our determination to invest in the paper packaging industry stems from our firm commitment to protecting the environment and moving with high sustainability, and we are willing to make our contribution to promote environmental protection.